Systematic review of the literature of green supply chain management in the food packaging industry*

Renzo Ernesto Chumpitasi Ortigas

https://orcid.org/0000-0003-1921-1388

Universidad de Lima, Facultad de Ingeniería, Lima, Perú

Valeria Gonzales Campana**

https://orcid.org/0000-0003-3329-0342

Universidad de Lima, Facultad de Ingeniería, Lima, Perú

Recibido: 18 de agosto del 2023 / Aceptado: 26 de septiembre del 2023

doi: https://10.26439/ing.ind2023.n45.6599

ABSTRACT. The awareness of green supply chain management (GSCM) has grown in the past year, particularly in the food packaging industry, due to population growth and its environmental impact. To explore this, we studied global perspectives on and contributions to GSCM, aiming to apply insights to developing countries. Our research revealed three main barriers hindering GSCM adoption in emerging economies: limited knowledge, inadequate technology, and high costs. By examining several authors’ viewpoints, we created a timeline showcasing GSCM’s evolution, enabling targeted improvements within the food packaging industry. Through this analysis, our paper not only reaffirms its initial objectives but also provides a foundation of tools and information for future GSCM research. This work contributes to the understanding of GSCM’s benefits and challenges, facilitating sustainable practices in a vital industry.

KEYWORDS: green supply chain management / supply chain / food industry / packaging and sustainability

* Este estudio no fue financiado por ninguna entidad.

** Autor corresponsal.

Correos electrónicos en orden de aparición: [email protected]; [email protected]

REVISIÓN SISTEMÁTICA DE LA LITERATURA SOBRE GESTIÓN

DE LA CADENA DE SUMINISTRO VERDE EN LA INDUSTRIA

DEL ENVASADO DE ALIMENTOS

RESUMEN. La concienciación sobre la gestión de la cadena de suministro verde (GCSV) ha crecido en el último año, especialmente en la industria del envasado de alimentos, debido al incremento de la población mundial y su impacto medioambiental. Para explorar esta cuestión, se estudiaron las perspectivas y las contribuciones mundiales a la GCSV, con el objetivo de aplicarlas a los países en vías de desarrollo. El presente artículo revela tres barreras principales que dificultan la adopción de la GCSV en las economías emergentes: conocimientos limitados, tecnología inadecuada y costes elevados. Examinando los puntos de vista de varios autores, construimos una línea de tiempo que muestra la evolución de la GCSV, la cual permite mejoras específicas dentro de la industria del envasado de alimentos. Gracias a este análisis, el artículo no solo reafirma sus objetivos iniciales, sino que también proporciona una base de herramientas e información para futuras investigaciones sobre GCSV. Este trabajo contribuye a la comprensión de los beneficios y retos de la GCSV, lo que facilita prácticas sostenibles en una industria vital.

PALABRAS CLAVE: gestión de la cadena de suministro verde / cadena de suministro / industria alimentaria / envasado y sostenibilidad

1. INTRODUCTION

A supply chain is defined as a system of activities related to the design, coordination, and control of materials and finished products, among others (Lazar et al., 2021). In the last decade, environmental awareness has increased due to the harmful consequences of pollution. Thus, manufacturing companies have tried to implement eco-friendly activities, particularly in the supply chain. Supply chain management is a recurrent concern, escalating to new ways of achieving supply and demand fulfillment in a cost-effective way (Kumar et al., 2018). A good supply chain management becomes a key factor for business management and generates a competitive advantage (Petljak, 2019). However, supply chains have the greatest impact on the environment. The integration of sustainability principles in the supply chain is a key issue that affects corporate competitiveness in the current socioeconomic and environmental context (Batista et al., 2019).

The supply chain has become a component that influences customers’ decisions because they are more aware of the importance of incorporating social responsibility in business management (Saidi et al., 2020). That is why price no longer has the relevance it used to have; at present, innovation, sustainability, and product optimization have a significant weight in costumer decisions (Leu et al., 2021).

This is how the concept of green supply chain management or GSCM was born, in the way of implementing environmental thinking within logistics processes (Yildiz Çankaya & Sezen, 2019). This can be defined as the process that uses eco-friendly inputs or materials and converts them into green products that can be recovered and reused after their life cycle, creating eco-friendly supply chains (Rahman et al., 2020). At a time when consumers demand more sustainable businesses, companies are trying to gain a competitive advantage by implementing green practices (Jayant & Azhar, 2014). In the report published by Statista Research Department (2016), 33 % of consumers in the US consider that the use of an eco-friendly package is a must and 19 % are proud of using them. The implementation of GSCM involves all stages of the production process, from initial operations to end consumers (Yildiz Çankaya & Sezen, 2019).

Sustainable supply chain management has increased its importance and the knowledge in the field follows the same trend (Saidi et al., 2020). GSCM becomes the most successful sustainability practice for every industry (Khan et al., 2022).

GSCM is an improvement strategy or policy that integrates environmental concerns with supply chain management practices (Ososanmi et al., 2022) and has five dimensions: green purchasing, eco-design, customer cooperation with environmental concerns, and reverse logistics (Liu et al., 2020). However, while GSCM has so far been researched for environmental practices, there is no comprehensive approach as well as some discrepancies between the terminology and differences in the understanding of GSCM and its purpose in the available literature (Petljak, 2019). Although there is an extensive literature, there are no articles that provide guidelines to put GSCM into practice (Assumpção et al., 2019).

From different industries, the ecological impact of packaging waste is a global problem that has become a matter of discussion in both the public and scientific spheres (Obersteiner et al., 2021). In 2019, 31,02 % of plastic was used in the packaging industry. Furthermore, by 2027, it is estimated that the plastic market size will increase to 385,5 million dollars according to Statista Research Department (2016). Thus, in the search for sustainable solutions to the increasing environmental pollution, we found that the amount of packaging waste is significant: 40 % of plastics are petroleum-based, and half of them come exclusively from the food packaging industry (Kleine Jäger & Piscicelli, 2021). In the same way, other authors point out that there is a growing trend in the global food industry, and that 37 % of plastics are used by the packaging industry (Farrukh et al., 2022). Based on the population growth, it is expected that the consumption of plastics and particularly of packaged foods will increase. Thus, packaged food supply chain has become relevant. This consists of all activities, organizations, actors, technologies, information, resources, and services that are related to food production until it reaches end consumers (Angarita-Zapata et al., 2021).

Only in the United States food industry is responsible for 20 % to 30 % of environmental damage (Simms et al., 2020). In 2017, approximately 30 kg of plastic packaging waste was generated per inhabitant per year in Europe (Geueke et al., 2018). Moreover, it has been observed that 95% of packaging is discarded after a first use (Kleine Jäger & Piscicelli, 2021). By the end of 2021, only 6,5 % of plastic was recycled. Therefore, sustainable packaging is a necessity to provide greater product innovation and competitiveness (Mattia et al., 2021). Based on the above, it is evident the need for solutions to the current problems to successfully implement GSCM in the food packaging industry.

As a result, this question was posed: What is the impact of the implementation of GSCM in the food packaging industry in developing countries? Therefore, the general objective was to determine the progress of GSCM in the food packaging industry, and the specific objectives were as follows:

- Identify the most relevant barriers to green supply chain adoption in developing countries.

- Analyze the different definitions of GSCM over time.

- List the different tools that have been developed in GSCM as well as their objectives.

- Synthesize the results of different studies of GSCM over the last decade.

- Determine the possible factors for improving the food packaging industry within the green supply chain.

2. METHODOLOGY

The method used in this research was a systematic scientific literature review, which allowed us to research different authors, gather their contributions, and analyze them in order to obtain new knowledge. Thus, different databases—Proquest, Scopus, and Web of Science—were used to answer the research question “What is the impact of the implementation of GSCM in the food packaging industry in developing countries?”.

Some keywords were used to guide the search in these databases, conduct the research and obtain specific results related to the topic and research question. These words were sustainability, supply chain, food packaging, and green supply chain management.

It should be noted that a certain combination of words was used to have accurate results, so keywords and Boolean operators were used.

Similarly, temporality as well as other criteria were considered as inclusion and exclusion criteria:

- Temporality: To ensure that the studies to be reviewed were the most recent ones, a filter to exclude all those articles older than five years was used, i.e., only papers from 2017 to the present were considered.

- Access: To have access, the Open Access option had to be set.

- Type of document: Only scientific articles were chosen.

- Language: Only papers in English and Spanish were used.

- Subject: Once all the abovementioned filters were established, there was only one left: To delimit the articles related to the research topic and question, we selected all the articles that had similarities with what was intended to be asked.

Based on an exhaustive search of articles and applying the inclusion and exclusion criteria, several tables were designed to better analyze the selected articles. Consequently, different characteristics were evaluated, including the years of publication, the database from which they were extracted, and the number of citations.

This review consists of publications from 2017 to 2022. Most of the selected articles were published in 2021, accounting for 34,08 % of the total. Thus, we have a wide range of recent articles with the latest knowledge and advances in GSCM. Moreover, there is a significant number of articles on the topic published in 2022, so it is a good indicator that knowledge of the subject continues to grow.

As mentioned before, the databases used in the research were Proquest, Scopus, and Web of Science. Relevant information can be found in Table 1. It is evident that Web of Science was the database with the least number of articles (30,23 %). The sources retrieved from each database were analyzed and duplicate sources were removed.

Table 1

Percentage of Extracted Articles with Respect to the Filtered Database

|

Database |

Total |

Percentage |

|

Proquest |

15 |

34,88 % |

|

Scopus |

15 |

34,88 % |

|

Web of Science |

13 |

30,23 % |

|

Total |

43 |

100,00 % |

Finally, the number of times the article has been cited was considered. For the analysis of this point, ranges were used to better identify the analysis. Articles were grouped according to the number of times they were cited: a maximum of 20, between 20 and 40, and more than 40. Table 2 shows that most of the articles do not exceed 20 citations. They account for 55,81 % of the total number of articles. However, there are four articles that have been cited more than 40 times: they are considered the most important to analyze in this research.

Table 2

Percentage of Extracted Articles with Respect to the Filtered Citations

|

Number of times cited |

Number of items |

Percentage |

|

1 to 20 |

24 |

55,81 % |

|

20 to 40 |

15 |

34,88 % |

|

40 and more |

4 |

9,30 % |

|

Total |

43 |

100,00 % |

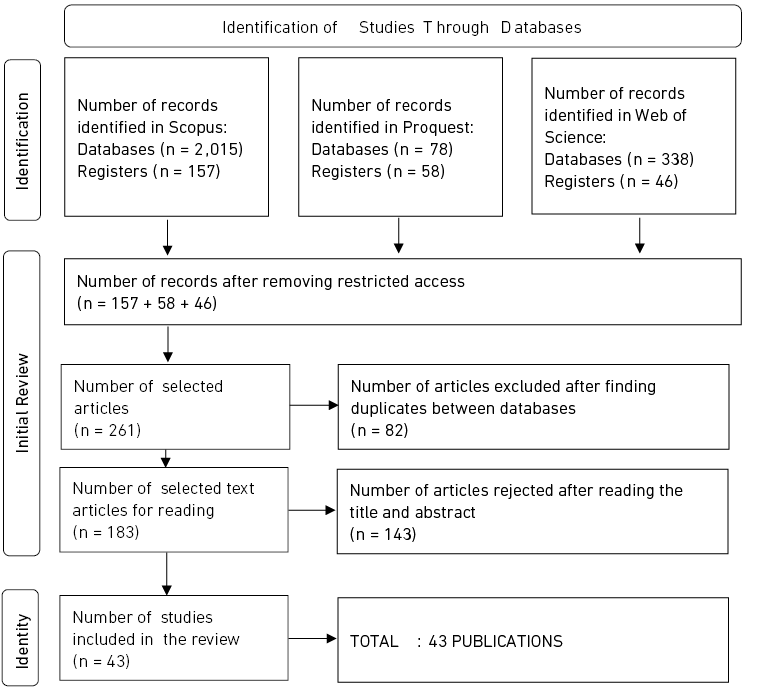

Using this information, the following scheme was developed to determine the number of articles that were analyzed and will be used for a subsequent research plan.

Figure 1

PRISMA Flow Diagram

3. RESULTS AND DISCUSSION

After reading the scientific literature retrieved and shown in the PRISMA flow diagram, a detailed analysis of GSCM and food packaging industry was carried out. From this reading and analysis, it was possible to determine the points shared by the authors, which will be highlighted in the following pages.

In many industries there are different barriers to the adoption of GSCM, particularly in the manufacturing industry. These barriers increase in developing countries and start from the company’s resistance to the adoption of green technologies and the lack of information about them. More barriers were identified as shown in Table 3.

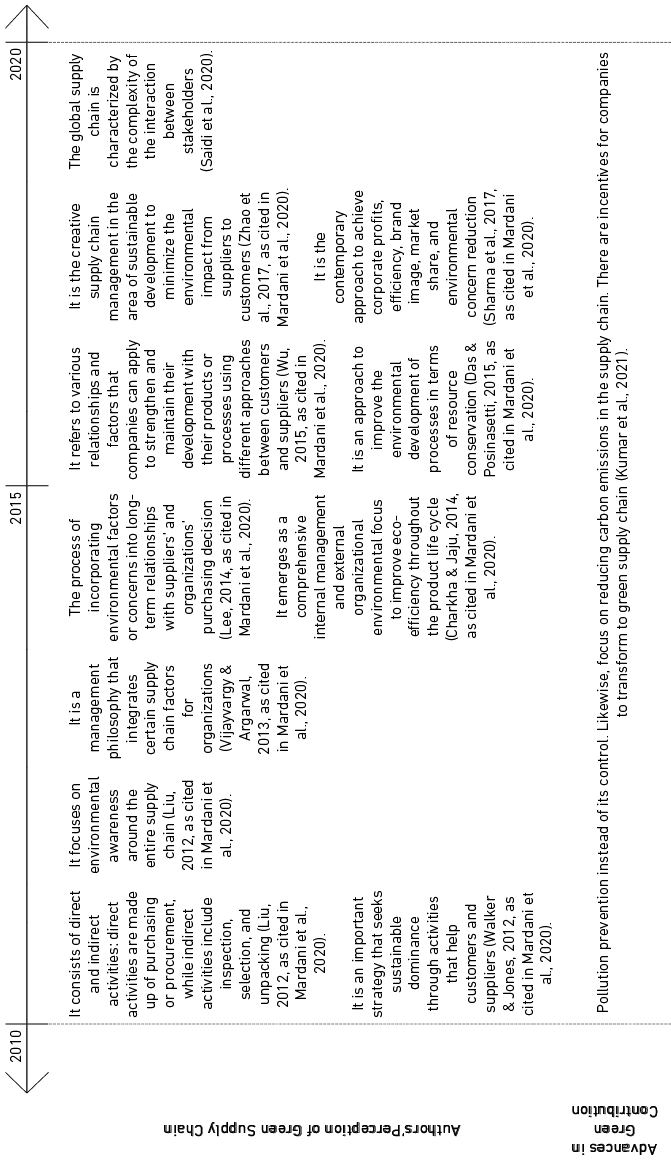

It was also possible to identify the tools used by various authors. The purpose of this was to gather more information, both qualitative and quantitative, on the perspective of workers and employers regarding the adoption of GSCM. With these contributions and an analysis of the evolution of the term GSCM, we were able to create a timeline, which is shown from Figure 2 to Figure 5.

Finally, we considered making a summary table of the contributions in GSCM from 2012 to 2021, as well as the factors that the food packaging industry must improve.

Table 3

Summary of GSCM Barriers

|

Barrier |

Description |

Author |

|

Lack of collaboration between government and environmental institutions |

Weak relationships between business and government hinder an effective green process. Therefore, collaboration is essential for the adoption of green innovation. |

Assumpção et al., 2019; Kumar et al., 2018; Laari et al., 2018; Liu et al., 2020; Movahedipour et al., 2017; Ososanmi et al., 2022; Saeed et al., 2018; Tundys & Wiśniewski, 2018; Ullah et al., 2021. |

|

Uncertainty about the effectiveness of green innovation |

Green innovation is risky in terms of uncertainty about return prospects. |

Aslam et al., 2018; Saidi et al., 2020; Ullah et al., 2021. |

|

Fear of failure about green innovation |

Critical factor due to not knowing what the effect will be both for the market and for their own production processes. |

Movahedipour et al., 2017; Rahman et al., 2020; Simms et al., 2020; Ullah et al., 2021; Vernier et al., 2021; Waqas et al., 2018. |

|

Lack of new technology |

The degree of technological information to understand green innovation is at a high level, but companies give little information due to sustainability constraints. |

Assumpção et al., 2019; Clark et al., 2019; Farrukh et al., 2022; Hebaz & Oulfarsi, 2021; Movahedipour et al., 2017; Rahman et al., 2020; Simms et al., 2020; Ullah et al., 2021; Waqas et al., 2018. |

|

Lack of market information |

Green innovation requires certain information to successfully adopt eco-practices in the marketplace. |

Assumpção et al., 2019; Batista et al., 2019; Clark et al., 2019; Farrukh et al., 2022; Hebaz & Oulfarsi, 2021; Jum’a et al., 2022; Movahedipour et al., 2017; Rahman et al., 2020; Simms et al., 2020; Ullah et al., 2021; Waqas et al., 2018; Yadav et al., 2021. |

|

High cost of implementing a green innovation system |

High costs associated with manufacturing green products make it difficult to adopt green practices. |

Aslam et al., 2018; Assumpção et al., 2019; Hebaz & Oulfarsi, 2021; Jum’a et al., 2022; Khan et al., 2022; Laari et al., 2018; Li & Zhu, 2020; Movahedipour et al., 2017; Rahman et al., 2020; Saidi et al., 2020; Santos et al., 2019; Simms et al., 2020; Tundys & Wiśniewski, 2018; Ullah et al., 2021; Vernier et al., 2021; Wang et al., 2021; Waqas et al., 2018. |

|

Keeping suppliers aware of environmental impact |

Industries are not able to keep suppliers informed of the necessary environmental policies. |

Cristóbal et al., 2018; Kumar et al., 2018; Movahedipour et al., 2017; Ullah et al., 2021; Waqas et al., 2018. |

|

Uncertainty in demand for green innovative products |

Demand for green products is uncertain due to high costs and returns, so companies are hesitant to produce them. |

Cristóbal et al., 2018; Kumar et al., 2018; Movahedipour et al., 2017; Ullah et al., 2021; Waqas et al., 2018. |

|

Lack of rules and regulations for green practices |

Unclear rules, poor enforcement of environmental laws and regulations that do not bind companies to follow environmental regulations. |

Aslam et al., 2018; Cristóbal et al., 2018; Lisec et al., 2017; Movahedipour et al., 2017; Rahman et al., 2020; Simms et al., 2020; Ullah et al., 2021; Waqas et al., 2018. |

|

Barriers in business practices |

Lack of management in green practices, misperception about green innovation and technology initiatives. |

Cristóbal et al., 2018; Hebaz & Oulfarsi, 2021; Jum’a et al., 2022; Khan et al., 2022; Kumar et al., 2018; Laari et al., 2018; Leu et al., 2021; Liu et al., 2020; Mattia et al., 2021; Movahedipour et al., 2017; Saeed et al., 2018; Ullah et al., 2021; Waqas et al., 2018. |

|

Lack of training and seminars related to green innovation |

Lack of training programs and insufficient workforces due to the lack of motivation on the part of workers and employers to carry out green activities. |

Hebaz & Oulfarsi, 2021; Kumar et al., 2018; Movahedipour et al., 2017; Santos et al., 2019; Ullah et al., 2021; Waqas et al., 2018. |

|

Lack of knowledge related to green innovation and practices |

Lack of knowledge and awareness blocks the innovation process. |

Angarita-Zapata et al., 2021; Assumpção et al., 2019; Cristóbal et al., 2018; Hebaz & Oulfarsi, 2021; Kleine Jäger & Piscicelli, 2021; Kumar et al., 2018; Movahedipour et al., 2017; Petljak, 2019; Petljak et al., 2018; Rahman et al., 2020; Saeed et al., 2018; Saidi et al., 2020; Simms et al., 2020; Tundys & Wiśniewski, 2018; Tuni et al., 2018; Ullah et al., 2021; Waqas et al., 2018. |

Thus, we can determine that the three main barriers to the implementation of GSCM in the food packaging industry are: lack of knowledge related to green innovation and practices, lack of new technology, and high cost of implementing a green innovation system. The first barrier is reinforced by 17 authors who, based on their research works, determined that the lack of knowledge and awareness of innovative processes inhibits companies from adopting GSCM practices. The second barrier, lack of new technology, is supported by the resistance of companies to adopt innovative processes and machines. In addition, this barrier refers to the fact that in developing countries, technology in industrial processes sometimes does not reach the country. Finally, the high cost of implementing a green innovation system, depending on the industry, may require high investment. In the case of developing countries, importing technologies and getting advice imply additional costs.

Our analysis showed that the barriers are not mutually exclusive but rather correlated. As Saidi et al. (2020) point out, the first challenge is to be efficient. This requires cost control and the certainty that the product will not be rejected by the market. On the other hand, it is also mentioned how the perception of the companies is not clear. Improving the barrier related to suppliers could also increase the good perception about these practices (Petljak, 2019).

However, while some authors argue that GSCM does not receive support from the government or other institutions because of resistance to change (Kumar et al., 2018), there is evidence in the literature that the aforementioned support exists and even better results are required without providing enough tools and legal or financial resources (Assumpção et al., 2019).

Table 4

Summary of the Results of Different Studies Based on the Adoption of GSCM

|

Year |

Contributions |

|

2012 |

Factor analysis and multiple linear regressions prove that GSCM internal and external factors must be coordinated to increase performance. External factors include the relationship between suppliers and customers through the implementation of reverse logistics and green purchasing, while internal factors refer to an eco-design contemplating energy and materials in the process. |

|

2014 |

A correlation was found between internal environmental management practices, eco-design and return on investment, and technological innovation. However, no relationship was found between green purchasing, customer cooperation, and technological innovation. |

|

2016 |

The most effective way to evaluate supply chain management performance is through green design, logistics, and green transformation. |

|

2016 |

The most important component for the implementation of GSCM processes is green procurement, followed by green transportation and green manufacturing. |

|

2018 |

There is a relationship between organizational learning mechanisms, organizational support, and the use of control variables in GSCM (organizational size, country perspective, firm’s cost pressure, and industry practices at various levels). |

|

2018 |

Using GSCM practices reduces environmental pollution and operating costs, but it does not increase the organization’s flexibility. |

|

2021 |

There is a positive effect of partial meditation of operational performance between GSCM, environment, and financial performance, as well as an effect of external pressure on the relationship between GSCM and operational success. |

|

2021 |

GSCM methods mitigate the impact of Industry 4.0 in both its economic and environmental consequences. |

Table 4 shows the results of different studies on the adoption of GSCM. Research conducted in 2012 and 2014 referred to the need of taking into account internal and external factors for a complete implementation of GSCM. Research conducted in 2018 determined that GSCM practices reduce environmental pollution and operating costs and increase the organization’s flexibility. Finally, in 2021, the literature reviewed operational success, as well as the positive effect on external pressure, to reduce the environmental effects linked with GSCM.

Table 5

Tools and Objectives for the Development of Supply Chain Strategies

|

Tool |

Objectives for Strategy Development Within the Supply Chain |

Authors |

|

Qualtrics application (software for data distribution and processing) |

From a production point of view, it will be shown how the adoption of green practices with suppliers impacts performance. |

Santos et al., 2019. |

|

CFA and LPA |

Attempt to analyze confidence in sustainability and business competitiveness aimed at finding a correlation between the practices of different companies. |

Laari et al., 2018. |

|

CFA |

Evaluation of how to increase the sustainability of a company’s internal supply chain processes. |

Leu et al., 2021. |

|

Co-design workshop sheets |

Evaluation of consumer behavioral insights into food to go processes with the purpose of making it greener. |

Clark et al., 2020. |

|

DM |

Evaluation of the impact of enterprise resource planning for sustainable supply chain and future strategy development. Development of green supply chain strategies from a sustainable perspective, strategy, and emerging economies. Evaluation of supplier selection based on environmental factors for the technology industry. Evaluation of critical problems in the sustainable logistics chain and reverse logistics. |

Waqas et al., 2018. |

|

EBM and LTS(A,A,A) models |

Implementation of the EBM and LTS models; attempt to predict the efficiency of packaging in the supply chain (done across 10 packaging companies). |

Waqas et al., 2018. |

|

Fuzzy VIKOR approach |

Observation of the barriers to GSCM and managing to classify their importance to take an action plan. |

Waqas et al., 2018. |

|

LCA and programming |

Plan for packaging waste to maximize the benefits of environmental prevention. |

Waqas et al., 2018. |

|

Various methods, including key performance indicator (KPI) analysis |

Finding the relationship between green supply chain and the research questionnaire to find out the most frequently used methods and tools. |

Wang et al., 2021. |

|

MILP |

Designing a distribution channel that offers fresh food online in a sustainable way. |

Rahman et al., 2020. |

|

Multi-criteria decision-making |

Designing and implementing a method to create the package and layout of a product to enhance sustainability with the decision tool. |

Cristóbal et al., 2018. |

|

Principles of system theory in GF |

Evaluation of the sustainability of processes in different industries to assess their greening factor. |

Tundys & Wiśniewski, 2018. |

|

Purposive sampling |

Observing and analyzing green technologies to reduce waste. |

Yadav et al., 2021. |

Table 5 shows the tools used by different authors in their research and the objectives related to each of them. Several authors also used other not so common tools due to the objective of their studies. One example is Fuzzy VIKOR (Rahman et al., 2020), which is a combination of two tools: Fuzzy, to obtain the weight of the alternatives, and VIKOR, to evaluate the optimal alternative. Moreover, Laari et al. (2018), as the previous authors, apply a set of two tools to conduct their research, CFA and LPA, demonstrating the wide range of tools that can be used.

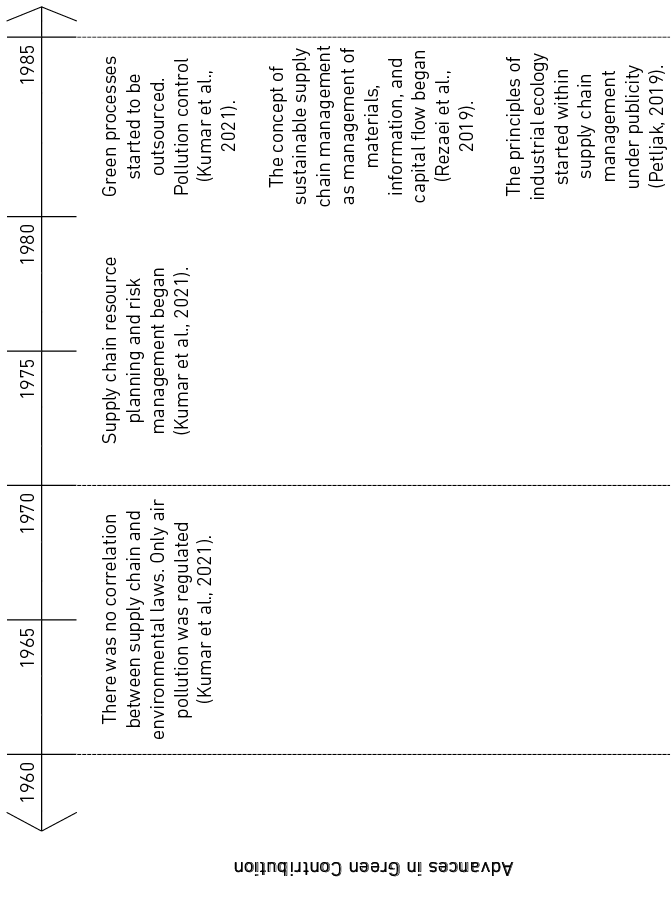

Figure 2

Timeline of the Evolution of GSCM (Part 1)

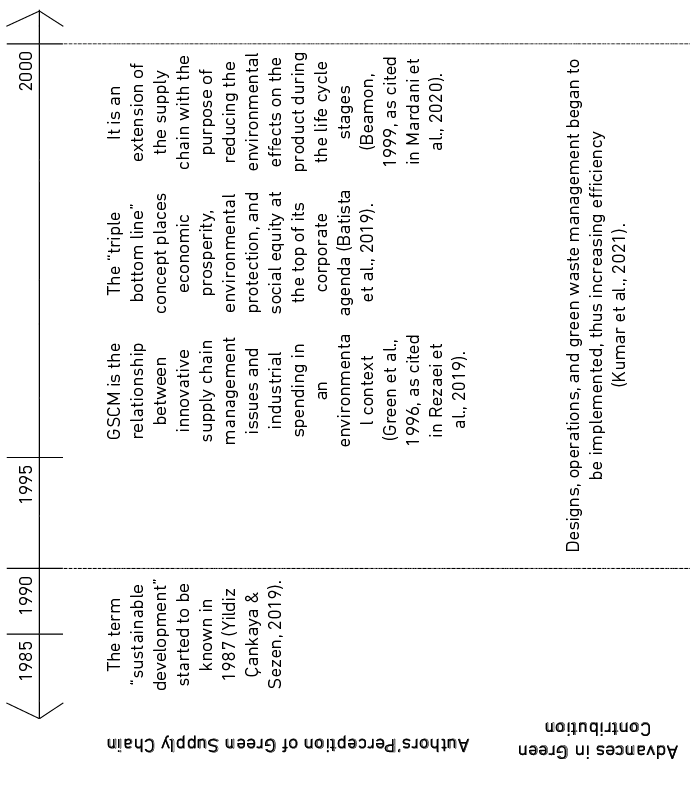

Figure 3

Timeline of the Evolution of GSCM (Part 2)

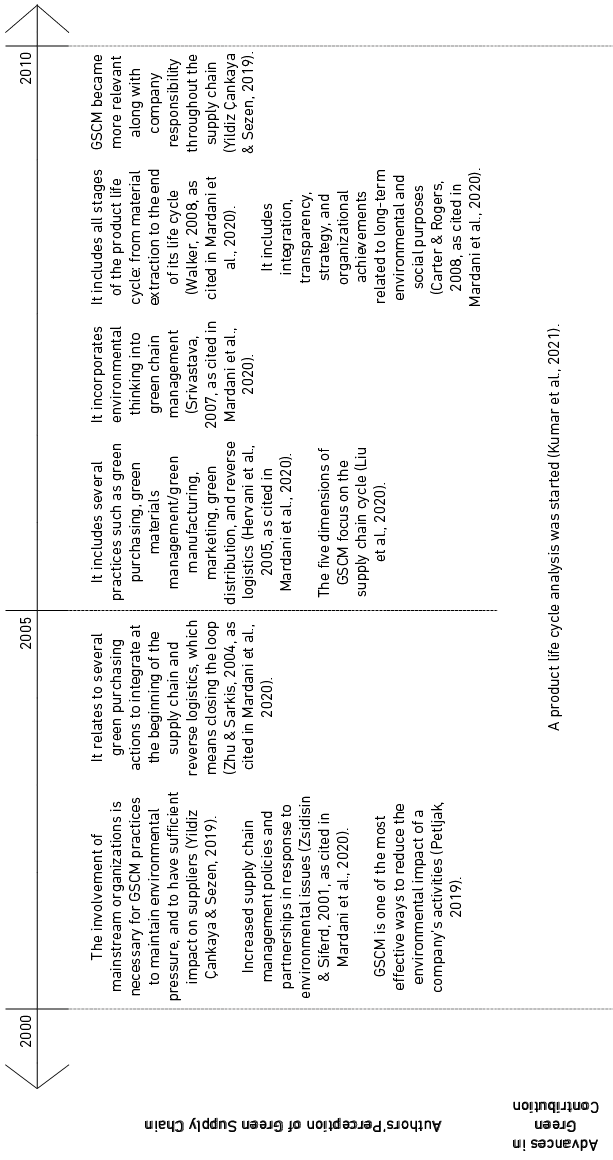

Figure 4

Timeline of the Evolution of GSCM (Part 3)

Figure 5

Timeline of the Evolution of GSCM (Part 4)

This timeline from Figure 2 to Figure 5 includes different authors’ perception of GSCM and the advances in green contribution. This timeline starts in 1960, the year in which GSCM was first discussed, until 2020, the year in which the importance of stakeholders in the supply chain was emphasized. While the last contribution made in the past decade was pollution prevention instead of its control, the aim is not to control pollutants but to eliminate them from the beginning of the chain. In the same way, it can be observed that the closer the timeline came to the present, the more evidence and contributions from the authors with their knowledge of the subject.

Table 6

Factors to be Improved in Food Packaging

|

Green Food Packaging Approach |

Source |

|

Optimization of waste transfer. |

Lisec et al., 2017. |

|

Eco-technologies approach only in the primary logistic chain. |

Simms et al., 2020. |

|

Circular economy for waste collection. |

Batista et al., 2019; Clark et al., 2019; Geueke et al., 2018; Mattia et al., 2021. |

|

Improved communication to suppliers about related costs and green performance. |

Li & Zhu, 2020; Mattia et al., 2021. |

In Table 6, we can identify that both circular economy and improved communication are important factors for the development and enhancement of supply chain in the food packaging industry. This is because circular economy ranges from communication on the use and recycling methods of packaging to addressing the refurbishment, repair, or reuse of packaging. Therefore, improving the communication with suppliers will allow constant negotiations to reduce the cost and improve the quality of recycled packaging.

Different authors propose approaches to address the green supply chain in food packaging. However, scholars offer different solutions. On the one hand, authors who agree on a circular economy approach to solve the packaging waste problem do not fully agree on how to reach this goal. While Clark et al. (2019) propose symbiosis in the industry by applying vertical integration, Batista et al. (2019) believe that a possible solution is to support third-party actors. However, Geueke et al. (2018) propose that maintaining an adequate recycling and optimization of packaging material is adequate, but it may have future recycling problems in aluminum that can result in the accumulation of other metals. Mattia et al., 2021 state their position of maintaining the support between the actors to optimize the process and achieve innovation and better ways of recycling.

4. TRENDS AND FUTURE CHALLENGES

As shown by the current scenario and the timeline shown in the previous section, the supply chain strongly focuses on achieving synergy between suppliers and customers. This means that the commitment of both parties to the environmental factors will be essential in the future. Future trends will see supply chains aiming to use recycled material in their products’ life cycle (Mattia et al., 2021). This means that packaging should be used as little as possible and reused as much as possible (Mattia et al., 2021).

Other authors argue that new areas—such as environmental purchasing, manufacturing, R&D, and distribution—will be of greater importance within GSCM planning (Tundys & Wiśniewski, 2018). It is worth noting that Laari et al. (2018) claim that a very important future advantage will be that those leaders who implemented GSCM from the beginning will find themselves at a competitive advantage by differentiating themselves from their competitors. This is because the green logistics trend will increase demand in the future and will be an important factor with benefits in the long term (Laari et al. 2018). All this—coupled with new trends such as the life cycle of the products—will take relevance, and the companies and their supply chains that best adapt will obtain benefits.

On the other hand, the future is not free of its own challenges since, as exemplified in the barriers, many of them are constant obstacles that are not solved with technological advances but with structural changes or modifications in the methodologies. Another future challenge is the standardization and correct definition of KPIs for GSCM so that they may be evaluated through different companies without confounding the factors to be assessed (Tundys & Wiśniewski, 2018). This means that, in the future, the various published research will need to focus on describing several KPIs to measure supply chain in terms of sustainable performance (Tundys & Wiśniewski, 2018). Similarly, Mattia et al. (2021) claim that one of the most complex goals to solve in the future is to reconcile technological and market advances with the shift towards sustainable packaging as a new form of consumer behavior.

5. CONCLUSIONS

As a result of the systematic literature review, we can determine that both the general objective and the specific objectives were achieved.

First, through the summary table of the academic articles used for this work, it was possible to establish not only the barriers to the implementation of GSCM but also to identify those that affect to a greater extent and are the most common within the food packaging industry, including high implementation cost, lack of knowledge, and lack of new technology. Therefore, strategies and possible solutions should be developed to facilitate the adoption of GSCM by companies.

Second, based on research conducted by different authors, a timeline from 1960 to the present day, which includes the different perspectives and contributions of various authors in the definition of GSCM, was created. This timeline also facilitated the understanding and evolution of the processes involved in GSCM in countries where the topic is more developed.

Third, a table summarizing the tools used by the different authors for their research and the objectives of each of them was made. Thus, it was possible to analyze the use of each of the tools according to the objective of the research. With this information, companies will be able to take strategic actions in GSCM within their organizations.

Moreover, it was possible to synthesize the different contributions from various research in GSCM per year. Thus, those results show the search for solutions and improvements, demonstrating that the literature is still interested in contributing to the subject.

Finally, we could algo identify the possible factors for improving the supply chain of the food packaging industry. In this way, an essential part will consist in improving the communication with suppliers about costs and green performance. This is because—if good practices are applied from the beginning of the chain—the generation of additional costs and a bad image for stakeholders will be prevented.

However, our review focused on the main factors that may contribute to or restrict GSCM in developing countries. It was also limited to the food packaging industry because of its large volumes of waste. This research did not consider other industries and whether there is any difference or similarity related to the industry.

It is recommended to conduct future research in Latin America because there is little information on the situation in Latin American countries. Therefore, by analyzing the current state, productivity, and contamination levels in the food packaging industry, it would be possible to motivate further research of new problems and solutions. This would be to contextualize the reader and perform a deeper analysis of the situation prior to the implementation of GSCM. Similarly, most of the studies analyzed only consider the business and theoretical approach without a wide range of proposals within companies.

Angarita-Zapata, J. S., Alonso-Vicario, A., Masegosa, A. D., & Legarda, J. (2021). A taxonomy of food supply chain problems from a computational intelligence perspective. Sensors, 21(20). https://doi.org/10.3390/s21206910

Aslam, H., Rashid, K., Wahla, A. R., & Tahira, U. (2018). Drivers of green supply chain management practices and their impact on firm performance: a developing country perspective. Journal of Quantitative Methods, 2(1), 87-113. https://doi.org/10.29145/2018/jqm/020104

Assumpção, J. J., Campos, L. M. de S., Jabbour, A. B. L. de S., Jabbour, C. J. C., & Vazquez-Brust, D. A. (2019). Green supply chain practices: a comprehensive and theoretically multidimensional framework for categorization. Production, 29. https://doi.org/10.1590/0103-6513.20190047

Batista, L., Gong, Y., Pereira, S., Jia, F., & Bittar, A. (2019). Circular supply chains in emerging economies: a comparative study of packaging recovery ecosystems in China and Brazil. International Journal of Production Research, 57(23), 7248-7268. https://doi.org/10.1080/00207543.2018.1558295

Clark, N., Trimingham, R., & Storer, I. (2019). Understanding the views of the UK food packaging supply chain in order to support a move to circular economy systems. Packaging Technology and Science, 32(11), 577-591. https://doi.org/10.1002/pts.2474

Clark, N., Trimingham, R., & Wilson, G. T. (2020). Incorporating consumer insights into the UK food packaging supply chain in the transition to a circular economy. Sustainability, 12(15). https://doi.org/10.3390/su12156106

Cristóbal, J., Castellani, V., Manfredi, S., & Sala, S. (2018). Prioritizing and optimizing sustainable measures for food waste prevention and management. Waste Management, 72, 3-16. https://doi.org/10.1016/j.wasman.2017.11.007

Farrukh, A., Mathrani, S., & Sajjad, A. (2022). A systematic literature review on environmental sustainability issues of flexible packaging: potential pathways for academic research and managerial practice. Sustainability, 14(8). https://doi.org/10.3390/su14084737

Geueke, B., Groh, K., & Muncke, J. (2018). Food packaging in the circular economy: overview of chemical safety aspects for commonly used materials. Journal of Cleaner Production, 193, 491-505. https://doi.org/10.1016/j.jclepro.2018.05.005

Hebaz, A., & Oulfarsi, S. (2021). The drivers and barriers of green supply chain management implementation: a review. Acta Logistica, 8(2), 123-132. https://doi.org/10.22306/al.v8i2.211

Jayant, A., & Azhar, M. (2014). Analysis of the barriers for implementing green supply chain management (GSCM) practices: an interpretive structural modeling (ISM) approach. Procedia Engineering, 97, 2157-2166. https://doi.org/10.1016/j.proeng.2014.12.459

Jum’a, L., Ikram, M., Alkalha, Z., & Alaraj, M. (2022). Factors affecting managers’ intention to adopt green supply chain management practices: evidence from manufacturing firms in Jordan. Environmental Science and Pollution Research, 29(4), 5605-5621. https://doi.org/10.1007/s11356-021-16022-7

Khan, M. T., Idrees, M. D., Rauf, M., Sami, A., Ansari, A., & Jamil, A. (2022). Green supply chain management practices’ impact on operational performance with the mediation of technological innovation. Sustainability, 14(6). https://doi.org/10.3390/su14063362

Kleine Jäger, J., & Piscicelli, L. (2021). Collaborations for circular food packaging: the set-up and partner selection process. Sustainable Production and Consumption, 26, 733-740. https://doi.org/10.1016/j.spc.2020.12.025

Kumar, V., Sabri, S., Garza-Reyes, J. A., Nadeem, S. P., Kumari, A., & Akkaranggoon, S. (2018). The challenges of GSCM implementation in the UK manufacturing SMEs. In 2018 International Conference on Production and Operations Management Society (POMS) (pp. 1-8). https://doi.org/10.1109/POMS.2018.8629449

Kumar, V., Sachdeva, A., & Pal Singh, L. (2021). A meta analysis of sustainable supply chain management from different aspects. International Journal of Supply and Operations Management, 8(3), 289-313. https://doi.org/10.22034/IJSOM.2021.3.4

Laari, S., Töyli, J., & Ojala, L. (2018). The effect of a competitive strategy and green supply chain management on the financial and environmental performance of logistics service providers. Business Strategy and the Environment, 27(7), 872-883. https://doi.org/10.1002/bse.2038

Lazar, S., Klimecka-Tatar, D., & Obrecht, M. (2021). Sustainability orientation and focus in logistics and supply chains. Sustainability, 13(6). https://doi.org/10.3390/su13063280

Leu, J.-D., Lee, L. J.-H., Huang, Y.-W., & Huang, C.-C. (2021). Sustainable supply chains: evidence from small and medium-sized manufacturers. Sustainability, 13(16). https://doi.org/10.3390/su13169059

Li, X., & Zhu, Q. (2020). Contract design for enhancing green food material production effort with asymmetric supply cost information. Sustainability, 12(5). https://doi.org/10.3390/su12052119

Lisec, A., Antić, S., Campuzano-Bolarín, F., & Pejić, V. (2017). An approach to packaging waste reverse logistics: case of Slovenia. Transport, 33(2), 1–9. https://doi.org/10.3846/16484142.2017.1326404

Liu, J., Hu, H., Tong, X., & Zhu, Q. (2020). Behavioral and technical perspectives of green supply chain management practices: empirical evidence from an emerging market. Transportation Research Part E: Logistics and Transportation Review, 140. https://doi.org/10.1016/j.tre.2020.102013

Mardani, A., Kannan, D., Hooker, R. E., Ozkul, S., Alrasheedi, M., & Tirkolaee, E. B. (2020). Evaluation of green and sustainable supply chain management using structural equation modelling: a systematic review of the state of the art literature and recommendations for future research. Journal of Cleaner Production, 249. https://doi.org/10.1016/j.jclepro.2019.119383

Mattia, G., di Leo, A., & Pratesi, C. A. (2021). Recognizing the key drivers and industry implications of sustainable packaging design: a mixed-method approach. Sustainability, 13(9). https://doi.org/10.3390/su13095299

Movahedipour, M., Zeng, J., Yang, M., & Wu, X. (2017). An ISM approach for the barrier analysis in implementing sustainable supply chain management. Management Decision, 55(8), 1824-1850. https://doi.org/10.1108/MD-12-2016-0898

Obersteiner, G., Cociancig, M., Luck, S., & Mayerhofer, J. (2021). Impact of optimized packaging on food waste prevention potential among consumers. Sustainability, 13(8). https://doi.org/10.3390/su13084209

Ososanmi, A. O., Ojo, L. D., Ogundimu, O. E., & Oke, A. E. (2022). Drivers of green supply chain management: a close-up study. Environmental Science and Pollution Research, 29(10), 14705-14718. https://doi.org/10.1007/s11356-021-16638-9

Petljak, K. (2019). Green supply chain management practices in food retailing. InterEULawEast: Journal for the International and European Law, Economics and Market Integrations, 6(1), 61–82. https://doi.org/10.22598/iele.2019.6.1.5

Petljak, K., Zulauf, K., Štulec, I., Seuring, S., & Wagner, R. (2018). Green supply chain management in food retailing: survey-based evidence in Croatia. Supply Chain Management: An International Journal, 23(1), 1-15. https://doi.org/10.1108/SCM-04-2017-0133

Rahman, T., Ali, S. M., Moktadir, Md. A., & Kusi-Sarpong, S. (2020). Evaluating barriers to implementing green supply chain management: an example from an emerging economy. Production Planning & Control, 31(8), 673-698. https://doi.org/10.1080/09537287.2019.1674939

Rezaei, J., Papakonstantinou, A., Tavasszy, L., Pesch, U., & Kana, A. (2019). Sustainable product-package design in a food supply chain: a multi-criteria life cycle approach. Packaging Technology and Science, 32(2), 85-101. https://doi.org/10.1002/pts.2418

Saeed, A., Jun, Y., Nubuor, S., Priyankara, H., & Jayasuriya, M. (2018). Institutional pressures, green supply chain management practices on environmental and economic performance: a two theory view. Sustainability, 10(5). https://doi.org/10.3390/su10051517

Saidi, D., El Alami, J., & Hlyal, M. (2020). Sustainable supply chain management: review of triggers, challenges and conceptual framework. In IOP Conference Series: Materials Science and Engineering. https://doi.org/10.1088/1757-899X/827/1/012054

Santos, H., Lannelongue, G., & Gonzalez-Benito, J. (2019). Integrating green practices into operational performance: evidence from Brazilian manufacturers. Sustainability, 11(10). https://doi.org/10.3390/su11102956

Simms, C., Trott, P., Van den Hende, E., & Hultink, E. J. (2020). Barriers to the adoption of waste-reducing eco-innovations in the packaged food sector: a study in the UK and the Netherlands. Journal of Cleaner Production, 244. https://doi.org/10.1016/j.jclepro.2019.118792

Statista Research Department. (2016). Sustainable food industry - statistics & facts. Statista.

Tundys, B., & Wiśniewski, T. (٢٠١٨). The selected method and tools for performance measurement in the green supply chain—survey analysis in Poland. Sustainability, 10(2). https://doi.org/10.3390/su10020549

Tuni, A., Rentizelas, A., & Duffy, A. (2018). Environmental performance measurement for green supply chains. International Journal of Physical Distribution & Logistics Management, 48(8), 765-793. https://doi.org/10.1108/IJPDLM-02-2017-0062

Ullah, S., Ahmad, N., Khan, F. U., Badulescu, A., & Badulescu, D. (2021). Mapping interactions among green innovations barriers in manufacturing industry using hybrid methodology: insights from a developing country. International Journal of Environmental Research and Public Health, 18(15). https://doi.org/10.3390/ijerph18157885

Vernier, C., Loeillet, D., Thomopoulos, R., & Macombe, C. (2021). Adoption of ICTs in agri-food logistics: potential and limitations for supply chain sustainability. Sustainability, 13(12). https://doi.org/10.3390/su13126702

Wang, C.-N., Hoang, Q.-N., & Nguyen, T.-K.-L. (2021). Integrating the EBM model and LTS(A,A,A) model to evaluate the efficiency in the supply chain of packaging industry in Vietnam. Axioms, 10(1). https://doi.org/10.3390/axioms10010033

Waqas, M., Dong, Q., Ahmad, N., Zhu, Y., & Nadeem, M. (2018). Critical barriers to implementation of reverse logistics in the manufacturing industry: a case study of a developing country. Sustainability, 10(11). https://doi.org/10.3390/su10114202

Yadav, V. S., Singh, A. R., Raut, R. D., & Cheikhrouhou, N. (2021). Design of multi-objective sustainable food distribution network in the Indian context with multiple delivery channels. Computers & Industrial Engineering, 160. https://doi.org/10.1016/j.cie.2021.107549

Yildiz Çankaya, S., & Sezen, B. (2019). Effects of green supply chain management practices on sustainability performance. Journal of Manufacturing Technology Management, 30(1), 98-121. https://doi.org/10.1108/JMTM-03-2018-0099