Study of the physical and mechanical properties of capirona (Calycophyllum spruceanum [Bentham] Hooker f. ex Schumann) wood as a potential for solid wood flooring production*

Graciela Isabel Egoavil Cueva Gálvez**

https://orcid.org/0000-0002-0895-7515

Universidad de Lima, Facultad de Ingeniería, Lima, Perú

Márcio Pereira da Rocha

https://orcid.org/0000-0002-5420-8478

Universidade Federal do Paraná, Facultada do Engenharia e Tecnologia Florestal, Paraná, Brasil

Ricardo Jorge Klitzker

https://orcid.org/0000-0001-6839-9415

Universidade Federal do Paraná, Facultada do Engenharia e Tecnologia Florestal, Paraná, Brasil

Pamela Carolina Castro Tamayo

https://orcid.org/0009-0009-2031-1133

Universidad Nacional Agraria La Molina, Facultad de Ingeniería, Lima, Perú

Recibido: 10 de julio del 2023 / Aceptado: 26 de julio del 2023

doi: https://doi.org/10.26439/ing.ind2023.n45.6505

ABSTRACT. The present study aimed to determine the physical and mechanical properties of a 20-year-old plantation of the species Calycophyllum spruceanum, known in Peru as “capirona,” for its potential for wood flooring production. For this purpose, samples were collected from six trees in a plantation located in the district of Curimaná, department of Ucayali, Peru. Physical and mechanical property tests were conducted following the American Society for Testing and Materials (ASTM) D143-94(2000) standard. The results showed that capirona has a basic density of 0,68 g/cm3, which is considered a heavy wood, and exhibits moderate dimensional stability. The mechanical properties demonstrated that the wood has a high resistance to bending and compression parallel to the grain, and a very high resistance to compression perpendicular to the grain, hardness, shear, and toughness. Based on the Peruvian Technical Standard (NTP) 251.135:2013, the characteristics of capirona wood for flooring were evaluated, yielding positive results and indicating its potential for solid wood flooring production.

KEYWORDS: plantations / physical and mechanical properties / solid wood flooring / plantation capirona / Ucayali

Estudio de las propiedades físico mecánicas de la madera

de capirona (Calycophyllum spruceanum [Bentham] Hooker

f. Ex Schumann) como potencial para la producción de pisos

de madera maciza

RESUMEN. El presente estudio tuvo como objetivo determinar las propiedades físico mecánicas de una plantación de veinte años, de la especie Calycophyllum spruceanum, conocida en el Perú como capirona, por su potencial para la producción de pisos de madera. Para ello, se tomaron muestras de seis árboles de una plantación ubicada en el distrito de Curimaná-Ucayali, Perú. Las pruebas de propiedades físicas y mecánicas se realizaron según los estándares de la Sociedad Americana para Pruebas y Materiales (ASTM D143-94 [2000]). Los resultados obtenidos mostraron que la capirona tiene una densidad básica de 0,68 g/cm3, por lo que se considera una madera pesada; además, presenta una estabilidad dimensional moderada. Las propiedades mecánicas mostraron que la madera presenta una alta resistencia a la flexión y compresión paralela y muy alta resistencia a la compresión perpendicular, dureza, cizallamiento y tenacidad. Con base en la NTP 251.135.2013, se evaluaron las características de la madera de capirona para pisos y arrojó resultados positivos que indican su potencial para la producción de pisos de madera maciza.

PALABRAS CLAVE: plantaciones / propiedades físico mecánicas / pisos de madera maciza / capirona plantada / Ucayali

* Este estudio no fue financiado por ninguna entidad.

** Autor corresponsal. Correos electrónicos en orden de aparición: [email protected]; [email protected]; [email protected]; [email protected]

1. INTRODUCTION

The timber industry in Peru is characterized by an extraction process mainly from natural forests, both legal and illegal. This situation has led to the degradation of natural forests, a progressive increase in operational costs due to the scarcity of wood, and a decrease in domestic production. On the other hand, it should be noted that in the Peruvian Amazon timber production is one of the most important economic activities, with natural forests being its main source of supply and subsistence (Servicio Nacional Forestal y de Fauna Silvestre [Serfor], 2021).

To address this problem, forest plantations are proposed as a viable alternative. By establishing these types of plantations, the negative impact on natural forests is reduced, national production is encouraged to increase, and illegal timber trade is combated. Additionally, this approach allows for continuous data recording and evaluation. However, the creation of these plantations can be expensive, so it is important to foresee potential risks that may result in economic losses and take measures to mitigate them. This process requires a comprehensive understanding of the species in terms of ecology, silviculture, and industrial aspects, which is currently scarce and not representative for most species (Guariguata et al., 2017).

Furthermore, there is a growing global trend in the utilization of wood from forest plantations, with greater relevance in the forestry industry sector (Cuellar & Reyes, 2016) as well as in the furniture industry, which is increasingly promising due to its increasing use, considering that the utilization of native woods is becoming more inefficient (De Carvalho et al., 2010). However, the limited information regarding their physical and mechanical properties restricts their application and may lead to losses for forest producers (Cuellar & Reyes, 2016).

Capirona is a species found throughout the Peruvian Amazon basin, southern Brazil, Colombia, and Bolivia. It tends to form dense stands known as “capironales,” and in some areas it can be extremely aggressive, making it an excellent alternative for plantations at altitudes ranging from 0 to 1,200 meters above sea level (Cuellar & Reyes, 2016). It is considered a fast-growing species with great economic potential, especially in the construction sector, where hardwood floors are highly demanded (Guariguata et al., 2017).

Due to its high density and hardness, capirona wood is highly valued for its quality. It is moderately easy to saw, moderately resistant to biological attack, and has good drying properties (Cámara Nacional Forestal [CNF], 1996). Because of its wide range of applications, it can be used in cabinetry, door and window manufacturing, moldings, turning, sports articles, crafts, food-contact utensils, among others (Sibille, 2006).

Currently, there are only plantations available for research and promotional purposes as a promising species. However, their demand is steadily increasing in the international market, particularly for flooring production, leading to unsustainable extraction without adhering to any management plan, and the wood from natural regeneration is insufficient to meet the growing needs of the forestry industry (Ushiñahua, 2016).

At the national level, the demand for capirona for parquet production is constantly increasing, ranking third in terms of parquet and floorboards production (Serfor, 2021). Additionally, capirona has been included in the business plan “Utilization and export of value-added timber products with FSC certification,” funded by Fondebosque in Madre de Dios (Urban, 2011). Regarding solid wood flooring, it is a non-structural, horizontal element made of solid or laminated wood, squared, with uniform thickness and cross-sectional area, which can have machined or smooth edges and ends, and a grooved or smooth top surface. It is used to cover a false floor, slab, screed, or base of a building (García, 2016).

Several research studies have been conducted on tropical woods for solid wood flooring. In Brazil, the focus has been on species such as sucupira (Bowdichia sp.), coumarou (Dipteryx odorata), ipé (Handroanthus sp.), tauari (Couratari spp.), among others. These studies aimed to characterize the physical and mechanical properties of these species to determine their potential as wood flooring materials (Teixeira et al., 2019). Teak (Tectona grandis) has been studied as a species with great potential for use in flooring, along with cedar (Cedrela odorata) and mahogany (Swietenia macrophylla). These species stand out for their combination of low specific weight and high strength, natural durability, ease of drying, and aesthetic beauty (Blanco-Flórez et al., 2015). On the other hand, Martins et al. (2013) conducted a physical, mechanical, and chemical characterization of Eucalyptus cloeziana, Eucalyptus microcorys, and Corymbia maculata woods to obtain valuable information to improve their utilization and consider them as a viable option in the flooring market. Research on tropical woods for solid wood flooring has provided valuable information about the properties of different species, offering interesting opportunities for their application in the construction of high-quality wood floors.

On the other hand, the country has vast expanses of deforested land that have yet to be utilized. According to data from Ministerio del Ambiente (Minam, 2022), the accumulated deforestation between 2001 and 2021 reached 2,774,562 hectares. A portion of these lands could be used to establish commercial plantations for industrial purposes. However, the production of primary transformation products—such as hardwood floors—from the Amazon region has been declining. This means that, if current consumption levels are maintained, the market will be forced to rely on increased product imports or utilize substitutes like plastic, ceramic, or metal, which would result in a loss of market position (Chávez, 2021).

Understanding the type and quality of wood through the evaluation of its physical, mechanical, anatomical, and chemical properties is critical for its proper use. Only scientific knowledge of wood will allow its utilization to move beyond artisanal practices and achieve the desired industrial processing (Feuchard, 2012).

Therefore, the objective of the present research on capirona from a 20-year-old forest plantation is to gather information about its physical and mechanical properties, with a focus on its basic density and hardness as key features for its use in the industrial production of solid wood floors.

2. MATERIALS AND METHODS

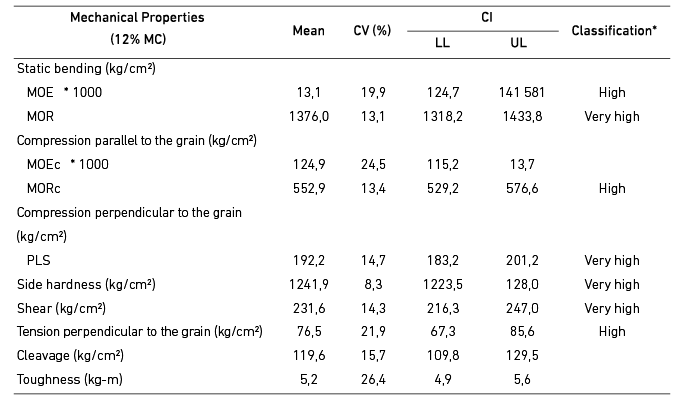

The trees were collected from a 20-year-old capirona (Calycophyllum spruceanum) plantation located in Cambio 90 village, district of Curimaná, province of Padre Abad, department of Ucayali, at UTM coordinates 486708, 486822, 486821, and 486748 meters East and 9071015, 9071075, 9071057, and 9070965 meters North. It is situated at an altitude of 169 meters and located 96 km from the city of Pucallpa. The climate in this area is warm and humid, with an annual precipitation ranging from 2,000 to 2,700 mm. The rainiest months are from October to March, with maximum temperatures ranging from 33 to 36o C between September and October, and minimum temperatures ranging from 17 to 20o C between June and July. The relative humidity ranges from 60 to 80 %

(Figure 1).

Figure 1

Geographical Location of the Capirona Plantation, District of Curimaná, Department of Ucayali

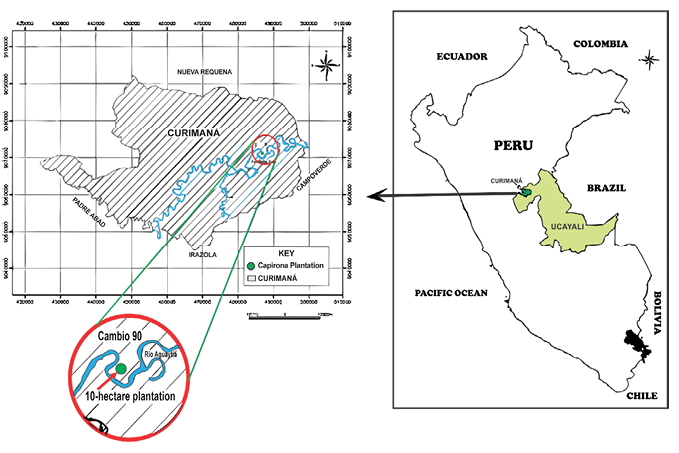

In order to determine the physical and mechanical properties, six trees were chosen based on their diameter and good phytosanitary condition. Once felled, a log was selected from each tree, ranging from the basal area to the diameter at breast height (DBH) with a length of 1,30 m. From each log, central blocks measuring 10 cm x 1.30 m in width and length, respectively, were obtained, with a variable thickness depending on the tree diameter (Figure 2). The preparation of the specimens was carried out at the Wood Preservation Laboratory, and the physical and mechanical tests were conducted at the Wood Technology Laboratory of the Faculty of Forestry Sciences at Universidad Nacional Agraria La Molina (UNALM) in Lima.

Figure 2

Obtaining Log Samples for Physical and Mechanical Tests

For the preparation of specimens, wood with knots (including the pith), splits, cracks, and without straight grain were avoided. They were then brought to a conditioned environment until they reached an equilibrium moisture content of 12 %. The tests for physical and mechanical properties were conducted following ASTM D143-94(2000): Standard Test Methods for Small Clear Specimens of Timber. Basic density, air-dry density, oven-dry density, moisture content, wood shrinkage, static bending, toughness, tension perpendicular to the grain, compression parallel to the grain, compression perpendicular to the grain, cleavage, shear, and hardness were tested.

A statistical description of the data was performed—including the point estimation of mean values, standard deviation, and coefficient of variation with their 95 % confidence intervals—for determining the overall means of the properties under study. All mechanical properties were compared with basic density using correlation analysis and simple regression analysis. The correlation analysis aimed to understand the association between the involved variables, with the basic density considered as the independent variable and the mechanical properties as the dependent variables.

The resulting data were compared with the Peruvian Technical Standard (NTP) 251.135:2013 for wood floors in order to evaluate the quality of capirona as a raw material for use in solid wood floors.

3. RESULTS AND DISCUSSION

3.1 Physical Properties

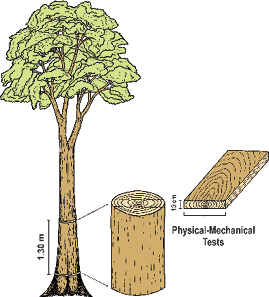

Table 1

Average Values of the Basic Density and Apparent Density at 12 % Moisture Content of Capirona Wood

Note. MC: moisture content; CV: coefficient of variation; UL: upper limit; LL: lower limit. *Source: Aróstegui et al. (1986).

The average basic density obtained was 0,68 g/cm3, ranging from a minimum value of 0,67 g/cm3 to a maximum value of 0,7 g/cm3, with a coefficient of variation of 8,5 % (Table 1). This low dispersion of the data indicates that the basic density in the 20-year-old plantation varies slightly from tree to tree. Aróstegui et al. (1986) states that basic density has a significant influence on mechanical properties, classifying wood according to its basic density into five groups. Capirona belongs to group IV (0,61 g/cm3–0,80 g/cm3), defining it as a wood with high basic density, which gives 20-year-old plantation capirona great potential for use in flooring production.

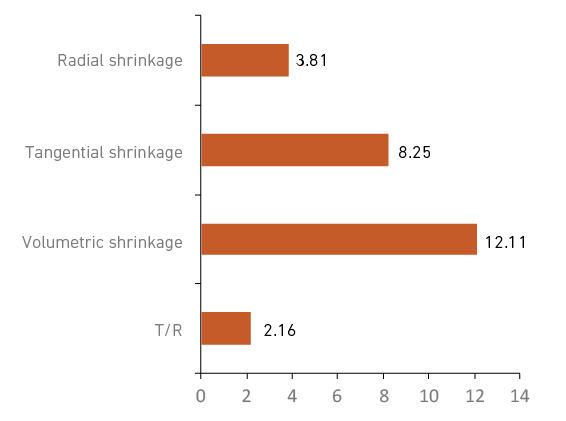

From the green state to reaching the equilibrium moisture content (12 %), the volumetric shrinkage was 12,11 %, with an anisotropy coefficient (T/R ratio) of 2.16. The tangential and radial linear shrinkage were 8,25 % and 3,81 %, respectively (Figure 3). According to the classification criteria by Sotomayor-Castellanos and Ramírez-Pérez (2013), the tangential shrinkage is classified as moderate and the radial shrinkage as low, while the volumetric shrinkage (12,11 %) is classified as moderate. Regarding the anisotropy coefficient (T/R ratio), Aróstegui et al. (1986) as well as Sotomayor-Castellanos and Ramírez-Pérez (2013) classify it as wood with moderate stability, while Klitzke (2003) classifies it as wood with moderate to high stability.

Figure 3

Average Shrinkage Values of Capirona Wood (percentage value)

Understanding the shrinkage and anisotropy coefficient allows for determining the percentage dimensional change that occurs in the wood due to the drying process (Fuentes-Talavera et al., 2014). Based on the abovementioned researchers, we can infer that the obtained results for shrinkage and anisotropy coefficient indicate that capirona wood has fairly acceptable dimensional stability, which is one of the requirements for wood suitable for flooring (Klitzke, 2003).

The tangential, radial, and volumetric shrinkage values of the wood are due to the normal dimensional changes in the wood’s three cutting planes. Aróstegui et al. (1986) attributes this to variations in moisture content below the fiber saturation point, resulting in the loss of hygroscopic water within the cellulose structure of the cell wall. This inflection point in moisture content represents the beginning of shrinkage during the drying process or swelling during adsorption, leading to dimensional changes in the wood (Kollmann & Côté, 1968).

The anisotropy coefficient (T/R ratio) is an index that reveals the dimensional stability of the wood, including distortions and warping. A higher coefficient indicates a greater likelihood of distortion or deformation in the piece of wood due to moisture changes during the drying process or when the wood is in service (Muñoz-Acosta & Moreno, 2013). Furthermore, Ananías (1992) states that higher values of this coefficient indicate more “nervous” woods, which can lead to dimensional changes and internal stresses, and lead to defects such as cracks and deformations during drying (Kollmann & Côté, 1968). If the dimensional changes are proportional to the changes in moisture content within the cell wall, it can be deduced that woods with higher density contain more hygroscopic water than lower-density woods at the same moisture content percentage, resulting in greater shrinkage (Aróstegui, 1982). Klitzke (2003) evaluates the quality of the wood based on its anisotropy, establishing that a piece of wood is considered very stable if its anisotropy coefficient is less than 1.5. If the coefficient falls within the range of 1.6 to 2, it is classified as moderate-low; whereas a coefficient between 2 and 2.5 is considered moderate-high. On the other hand, if the coefficient is greater than 2.6, the wood is classified as highly unstable.

This wood characteristic has a significant influence during the drying process. If the volume reduction exceeds the cohesion between cells, cracks, splits, and deformations may occur, particularly when drying is rapid. Therefore, the moderate stability value of capirona wood suggests that a mild and slow drying program should be used.

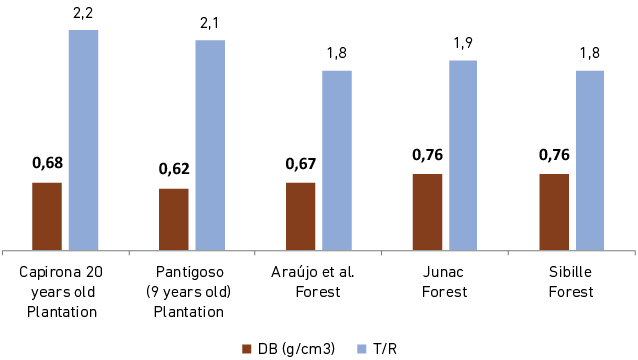

Comparing the basic density from this research with that from similar studies of the same species from plantations and natural forests (Figure 4), according to Pantigoso (2009), capirona shows an 8,82 % increase compared to wood from a nine-year-old plantation, with densities of 0,68 g/cm3 and 0,62 g/cm3, respectively. The trend is similar for natural forest capirona but with higher density values. This may be influenced by the differences in the specific gravity between earlywood and latewood (Moya & Muñoz, 2010). Additionally, this moderate increase, especially in the early stages, indicates that silvicultural factors have a significant influence on the increase in basic density (Pantigoso, 2009). On the other hand, the wood density found in this study is similar to that found by De Araújo et al. (2016) and lower compared to natural forest wood studied by Junta del Acuerdo de Cartagena (JUNAC, 1981) and Sibille (2006), which are of unknown ages.

Figure 4

Average Basic Density and Anisotropy Coefficient (T/R Ratio) of Plantation and Natural Forest Capirona Wood

It can be observed that the values of the shrinkage ratio (T/R ratio), which indicate the dimensional stability of the wood, are higher in woods from plantations than in those from natural forests. This is because plantation woods are younger and therefore have a higher proportion of juvenile wood compared to mature wood from natural forests. On the other hand, Aróstegui (1982) states that moisture and wood anisotropy are the most important factors involved and are also affected by climatic conditions such as relative humidity and temperature. Panshin and De Zeeuw (1981) argue that wood variability is also due to internal changes in the cambium related to age, genetic inheritance, among other factors. Tuset and Duran (1979) mention that external factors such as climate, soil conditions, and silvicultural conditions also play a role.

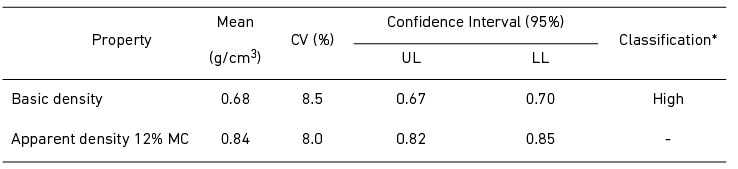

According to the wood classification proposed by Dávalos and Bárcenas (1999), capirona wood exhibits high values of modulus of elasticity (MOE) in bending, compression parallel to the grain (MORc), and tension perpendicular to the grain. It also shows very high values of modulus of rupture (MOR) in bending, compression perpendicular to the grain, side hardness, and shear (Table 2). These values are similar to those reported by Kretschmann (2010) for certain mechanical properties of woods. According to the classification by Aróstegui et al. (1986), the studied capirona wood displays very high toughness.

Table 2

Average Values of the Mechanical Properties of Capirona Wood

Note. MC = moisture content; MOE = modulus of elasticity; MOR = modulus of rupture; PLS = proportional limit of stress; CV = coefficient of variation; CI = confidence interval; UL = upper limit; LL = lower limit.*Source: Dávalos & Bárcenas (1999).

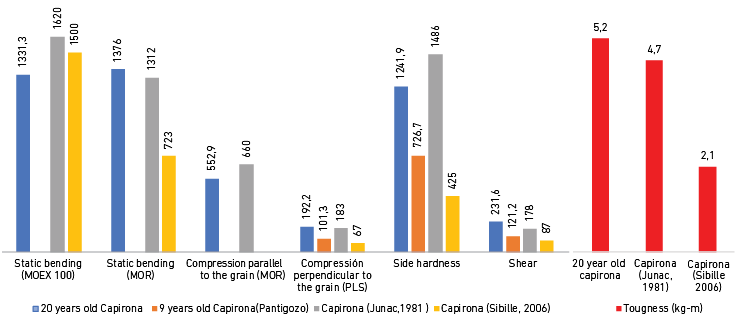

Figure 5 compares the values of the mechanical properties from the present study with those of works conducted by other researchers on capirona wood from a 9-year-old plantation (Pantigoso, 2009) and from natural forests (JUNAC, 1981; Sibille, 2006).

As for static bending, the mean value for MOE was 133 130 kg/cm2, lower than those obtained by JUNAC (1981) and Sibille (2006), with 162 000 kg/cm2 and 150 000 kg/cm2, respectively. However, regarding MOR, the value of 1376 kg/cm2 was similar to that of JUNAC (1981), with 1312 kg/cm2, but higher than that of Sibille (2006), with 723 kg/cm2. These results for dried plantation capirona indicate high and very high values for MOE and MOR, according to the classification by Dávalos and Bárcenas (1999). On the other hand, Echenique-Manrique and Plumptre (1994) suggest MOR values ranging from 400 kg/cm2 to 1350,5 kg/cm2 and MOE values from 710,2 kg/cm2 to 150 051,2 kg/cm2 as limits for structural uses, roofs, walls, and floors. The researched capirona wood falls within these limits, making it a good alternative for the production of the abovementioned products due to its high flexural strength.

Figure 5

Comparison of the Mechanical Properties of 20-Year-Old and 9-Year-Old Plantation and Natural Forest Capirona

Note. MOE = modulus of elasticity; MOR = modulus of rupture; PLS = proportional limit of stress.

MOR in compression parallel to the grain of 552,9 kg/cm2 is lower than the value reported by JUNAC (1981) for natural forest capirona wood, which is 660 kg/cm2. However, according to the classification by Dávalos and Bárcenas (1999), the researched capirona wood exhibits high resistance to compression parallel to the grain. It is worth noting that MOR in compression parallel to the grain is particularly important when the wood is intended for the production of columns or supports subjected to loads applied in a direction parallel to the grain (Fuentes, 1998). Therefore, its use as a structural material to make wooden beams for the construction industry is recommended.

Regarding the compression perpendicular to the grain, which is the resistance of the wood to forces applied in a direction perpendicular to the grain, the value obtained was 192,2 kg/cm2. This value is higher than those reported by Pantigoso (2009), JUNAC (1981), and Sibille (2006), with 101,3 kg/cm2, 183 kg/cm2, and 67 kg/cm2, respectively. According to the classification of mechanical properties by Dávalos and Bárcenas (1999), the researched capirona wood exhibits very high resistance to perpendicular compression forces. This property is particularly relevant when the wood is subjected to external loads that tend to compress it, such as in the case of sleepers exposed to high compression loads, making it suitable for such applications.

The average side hardness for capirona wood was 1241,9 kg/cm2, a value higher than those obtained by Pantigoso (2009) and Sibille (2006), with 726,7 kg/cm2 and 425 kg/cm2,

respectively, and only slightly lower than that obtained by JUNAC (1981), with 1486 kg/cm2.

Some studies claim that hardness increases with age, but different ages and sources of wood exhibit different behaviors. For example, the researched capirona wood showed higher hardness than Sibille’s (2006) natural forest capirona wood, while this was not the case for JUNAC’s (1981) wood, also from natural forests, where hardness increased with the age of the wood. It is worth noting that this property is particularly important when the wood is used for the production of floors, table surfaces, and any surface exposed to mechanical wear (Fuentes, 1998). Capirona wood is classified as a species with very high resistance, according to Dávalos and Bárcenas (1999), due to its hardness characteristics.

The value obtained for shear was 231,6 kg/cm2, higher than those reported by Pantigoso (2009), JUNAC (1881), and Sibille (2006), with 121,2 kg/cm2, 178 kg/cm2, and 87 kg/cm2, respectively. It should be noted that this property indicates the wood’s ability to resist forces that cut it parallel to its axis. The studied capirona exhibited a very high value, according to the classification of Dávalos and Bárcenas (1999), which suggests that it will perform well in assembly applications.

Regarding toughness, which is a very important property as a resilient material and refers to the wood’s ability to absorb energy when subjected to impact or shock, capirona wood obtained an average value of 5,2 kg-m. This value is higher than those obtained by JUNAC (1981) and Sibille (2006), with 4,7 kg-m and 2,1 kg-m, respectively. This higher value, compared to natural forest wood, provides greater advantages for its use in articles exposed to impacts, such as tool handles, sporting goods, floors, among others.

3.3 Predictions of Capirona Wood’s Mechanical Properties Based on Basic Density

Density is one of the most important properties of wood, as it determines most of its physical and technological properties. It also serves as a reference for wood classification, which is closely related to the anatomical characteristics and, in some cases, natural durability. Density is the most widely used characteristic in research related to wood quality, and it is the most important and best related to other properties (Moreschi, 2014). It is often considered a good estimator of the mechanical properties.

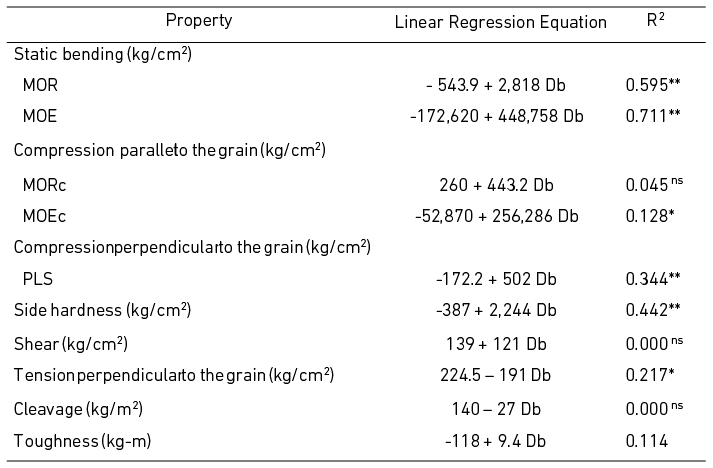

Table 3 shows the influence of basic density as a predictor of some mechanical properties using a simple linear regression model and the coefficient of determination R2. It can be observed that there is a high correlation between most of the mechanical properties.

Table 3

Prediction of the Mechanical Properties of 20-year-old Capirona Wood Based on Basic Density (Db) Using a Linear Regression Equation

Note. Db = basic density in kg/m3; MOR = modulus of rupture; MOE = modulus of elasticity; PLS = proportional limit of stress; R2 = coefficient of determination.

It can be observed that, in most of the mechanical properties of capirona wood, the coefficient of determination R2 was higher than 44,2 %, with the highest value for static bending MOE, where basic density accounted for 71,1 % of the MOE variation. In general, the basic density of capirona showed a positive and highly significant correlation with static bending, compression perpendicular to the grain, proportional limit of stress (PLS), hardness, and toughness. Additionally, there was a significant positive correlation with MOEc in compression parallel to the grain and a negative correlation in tension perpendicular to the grain. However, MORc in compression parallel to the grain and shear did not show a significant relationship.

According to the results in Table 3, the basic density of capirona wood positively influences most mechanical properties. Specifically, 50 % of the properties show a highly significant positive influence, 10 % exhibit a significant positive influence, 10 % display a significant negative influence, and only the remaining 30 % show no influence from the basic density. These results confirm the influence and, therefore, the importance of basic density in hardness and most of the mechanical properties of the capirona wood under study.

3.4 Behavior of the Physical and Mechanical Properties of Capirona Wood in the Wood Flooring Production Process

In the production of solid wood flooring, the physical and mechanical properties of the wood must be taken into account as they determine the quality and durability of the flooring. To achieve this, a brief overview of the production process will be provided.

The process begins by selecting the appropriate wood for flooring production; at this stage, it is crucial to consider its density and hardness. In general terms, denser wood will be more resistant and durable. Likewise, harder wood will be more resistant to impacts and wear, and less prone to scratching or denting with daily use (González-Trejos, 2012). The moisture content of the wood must be reduced before processing, which is achieved through wood drying. This process is essential to prevent deformations or damage to the finished floors; therefore, it is important for the wood to have adequate dimensional stability to avoid issues such as excessive shrinkage or expansion due to changes in humidity or temperature (Klitzke, 2003).

Then, the wood undergoes a planing and sanding process to achieve a uniform and smooth surface, free from imperfections, splinters, or roughness that the wood may have. If it has good workability characteristics, it will be easy to work with and process during flooring manufacturing, facilitating cutting, gluing, planing, among other operations. This allows for shorter production times, leading to more efficient and faster production, which is beneficial in terms of productivity and delivery schedules. It also results in greater precision and high-quality finishes, while minimizing material waste, reducing the amount of generated waste, and optimizing the use of raw materials (Hoadley, 2019; Porter, 2013).

Next, the wood is cut into thin planks or sheets of different widths, thicknesses, and lengths, according to the desired flooring. Adhesive and special glues are applied, and the planks are joined together to form the floor pieces. Once the planks are joined, a finish is applied to the surface of the floor to protect it and enhance its appearance. This may include varnishes, dyes, oils, or lacquers. Moreover, additional treatments are applied to improve the wear resistance, durability, and moisture resistance of the flooring (Hoadley, 2019; Porter, 2013).

Based on the described process of wood flooring production, capirona wood has favorable characteristics for flooring manufacturing. Its high density and hardness during the selection stage, good dimensional stability during the drying stage, and ease of machinability indicate that a high-quality product could be obtained from a productivity standpoint.

3.5 Analysis of Capirona Wood Quality for Hardwood Flooring

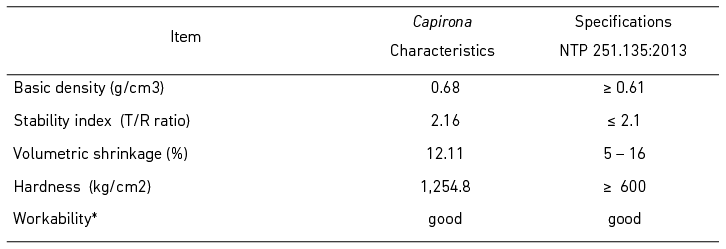

Table 4

Comparison Between the Physical and Mechanical Properties of Capirona Wood and the NTP 251.135:2013 for Wood Floors

*Source: Bustamante (2010).

According to Table 4, plantation capirona wood shows higher values in most of its properties compared to the characteristics established by the NTP 251.135:2013 for wood floors: solid tongue-and-groove parquet products from Peruvian wood species used in parquet manufacturing that meet the requirements of the national and international industry and trade.

The value obtained for basic density is 10,3 % higher than the minimum specified by the standard (≥ 0,61). This characteristic is of great importance due to its predictive capacity for the good performance of certain mechanical properties, such as hardness, which is one of the most important properties to be considered in raw materials for flooring production.

Regarding the stability index (T/R ratio), although it has a slightly higher value than that indicated by the standard, it may not be very relevant, as the wood for flooring is previously sawn into 1” (2.54 cm) thick planks. These dimensions in capirona help prevent distortions and warping, which is what this index measures, due to moisture changes during the drying process or when the wood is in service (Muñoz-Acosta & Moreno, 2013). Additionally, modern drying technologies such as vacuum drying allow for stabilizing the moisture content of the wood with satisfactory results in terms of drying quality.

The volumetric shrinkage is within the range specified by the standard, with

41,6 % above the lower range and 25 % below the higher range. It is worth noting that this characteristic is very important to understand the behavior of the wood during drying and to avoid cracks, splits, and deformations that may occur during the drying program, which would result in non-compliant products.

The hardness resistance presents a very high value compared to the minimum characteristic that a wood species must meet according to the NTP for wood floors

(≥ 600 kg/cm2), especially considering that it is one of the most important properties for flooring production since its surface will be exposed to mechanical wear due to high circulation or traffic.

Capirona wood also meets the NTP requirements as it exhibits good workability characteristics in terms of planing, molding, drilling, and turning. According to studies conducted on four species from forest plantations (marupa, tornillo, pino chuncho, and capirona), capirona showed the best workability characteristics (Bustamante, 2010), reducing working or machine hours and increasing productivity.

3.6 Uses of Capirona Wood

Based on the results obtained from the physical and mechanical properties of 20-year-old plantation capirona wood, it is considered a species with high basic density (Aróstegui et al., 1986) and great mechanical strength (Dávalos & Bárcenas, 1999). These characteristics make it highly versatile for various uses, including construction materials (structures, beams, and columns), exterior coverings such as flooring and parquet with excellent durability, carpentry (furniture, doors, frames, and windows), as well as tongue-and-groove boards, pallets, vehicle bodies, streetlight poles, and fences

(Cuellar & Reyes, 2016).

Capirona is one of the promising species with good potential to be introduced into the European and Japanese markets, which demand light brown or easily stainable woods (white or yellow colors), with an average density ranging from 0,5 g/cm3 to 0,75 g/cm3 (CNF, 1996). This species shares similarities with Japanese birch, which gives it a significant advantage for the production of structures, furniture, and especially for flooring. This suggests that plantation capirona would have not only domestic demand but also international demand, and if large-scale forest plantations were established, it would have a guaranteed market access. Furthermore, pre-feasibility studies to establish industrial plants for the production of solid wood flooring support this hypothesis, as their economic and financial indicators showed positive values (Arévalo, 2016).

4. CONCLUSIONS

- Capirona wood has a high basic density of 0,68 g/cm3 as well as dimensional stability and average volumetric shrinkage.

- Its mechanical properties showed high and very high values.

- The physical and mechanical properties of plantation capirona wood remain within the classification range compared to natural forest wood.

- The basic density of the species is a good estimator for approximately 70 % of the mechanical properties.

- The values of basic density, stability index, volumetric shrinkage, and hardness found in this research meet the technical specifications of the NTP for wood floors.

- Based on the physical and mechanical properties found, capirona (Calycophyllum spruceanum) can be used in the production of solid wood flooring.

American Society of Testing and Materials. (2000). ASTM D143-94: Standards methods of testing small clear specimens of timber. ASTM International. https://www.astm.org/DATABASE.CART/HISTORICAL/D143-94.htm

Ananías, R. (1992). Física de la Madera. Universidad del Bio-Bio, Departamento de Ingeniería en Maderas.

Arévalo, G. A. (2016). Estudio de prefactibilidad para la instalación de una planta productora de pisos de madera estructurada para el mercado limeño [Undergraduate thesis, Universidad de Lima]. Repositorio Institucional de la Universidad de Lima.http://doi.org/10.26439/ulima.tesis/5945

Aróstegui, A. (1982). Recopilación y análisis de estudios tecnológicos de maderas peruanas. Documento de trabajo N.º 2 PNUD/FAO/PER/81/002; Instituto Nacional Forestal y de Fauna; Ministerio de Agricultura.

Aróstegui, A., González, V., & Sato, A. (1986). Propiedades tecnológicas y usos de la madera de 40 especies del Bosque Nacional Alexander von Humboldt. Revista Forestal del Perú, 10(1-2), 1-86. http://cedinfor.lamolina.edu.pe/Articulos_RFP/Vol10_no1-2_80-81_(14)/vol10_art1.pdf

Blanco-Flórez, J., da Silva, J. R. M., Braga, P. P. C., Lima, J. T., & Trugilho, P. F. (2015). Simulação em serviço de pisos de madeira jovem de Tectona grandis. Matéria (Rio de Janeiro), 20(04), 1048-1060. https://doi.org/10.1590/s1517-707620150004.0107

Bustamante, N. R. (2010). Estudio de trabajabilidad de la madera de cuatro especies procedentes de plantaciones en la región Ucayali. Instituto Nacional de Innovación Agraria. https://repositorio.inia.gob.pe/handle/20.500.12955/386

Cámara Nacional Forestal. (1996). Utilización industrial de nuevas especies forestales en el Perú. PROYECTO OIMT PD 37/88.

Chávez, M. (2021, April 5). Perú y el mercado internacional de maderas que

puede aprovechar. La Cámara. https://lacamara.pe/peru-y-el-mercado-

internacional-de-maderas-que-puede-aprovechar/

Cuellar, J., & Reyes, P. (2016). ¿Es la Capirona Calycophyllum Spruceanum una opción rentable para la promoción de plantaciones forestales en la Amazonía? Instituto Nacional de Innovación Agraria. http://repositorio.inia.gob.pe/handle/20.500.12955/364

Dávalos, R., & Bárcenas, G. M. (1999). Clasificación de las propiedades mecánicas de las maderas mexicanas en condición “seca”. Madera y Bosques, 5(1), 61-69. https://www.redalyc.org/pdf/617/61750107.pdf

De Araújo, B. H. P., De Sousa, M. A. R., Nascimento, H. E. M., Zanuncio, A. J. V., Rodrigues, D. M. S., & Guedes, M. C. (2016). Propriedades físicas da madeira de Calycophyllum spruceanum Benth. em função do diâmetro e da posição (base e topo) no fuste. Scientia Forestalis, 44(111), 759-768. http://dx.doi.org/10.18671/scifor.v44n111.22

De Carvalho, A. M., Da Silva, B. T. B., & Latorraca, J. V. F. (2010). Avaliação da usinagem e caracterização das propriedades físicas da madeira de mogno africano (Khaya ivorensis A. Chev.). Cerne, 16, 106-114. https://www.redalyc.org/pdf/744/74459381014.pdf

Echenique-Manrique, R., & Plumptre, R. A. (1994). Guía para el uso de maderas de Belice y México. Oxford.

Feuchard, L. D. (2012). Propriedades tecnológicas da madeira de Casuarina equisetifolia. [Undergraduate thesis, Universidade Federal do Espírito Santo]. Biblioteca Forestal Digital. http://www.bibliotecaflorestal.ufv.br/handle/123456789/14162

Fuentes, M. (1998). Propiedades tecnológicas de las maderas mexicanas de importancia en la construcción. Revista Chapingo Serie Ciencias Forestales y del Ambiente, 4(1), 221-229.

Fuentes-Talavera, F. J., Silva-Guzmán, J. A., Rodríguez-Anda, R., Sanjuán-Dueñas, R., & Richter, H. (2014). Perfil de estabilidad dimensional de las maderas primavera y Rosa Morada. Revista Mexicana de Ciencias Forestales, 5(24), 56-69. https://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S2007-11322014000400006

García, F. F. (2016). Pisos de madera. Apuntes del curso de Industrias de Transformación Mecánica. Universidad Nacional Agraria La Molina, Facultad de Ciencias Forestales.

González-Trejos, G. (2012). Pisos de madera. Revista Forestal Mesoamericana Kurú, 3(7), 59-67. https://revistas.tec.ac.cr/index.php/kuru/article/view/529

Guariguata, M. R., Arce, J., Ammour, T., & Capella, J. L. (2017). Las plantaciones forestales en Perú: reflexiones, estatus actual y perspectivas a futuro (vol. 169). CIFOR. https://doi.org/10.17528/cifor/006461

Hoadley, R. B. (2019). Identifying Wood: Accurate Results with Simple Tools (3rd ed.). Taunton Press.

Junta del Acuerdo de Cartagena. (1981). Tablas de propiedades físicas y mecánicas de la madera de 24 especies de Colombia. Junta del Acuerdo de Cartagena PADT REFORT; Grupo Andino.

Klitzke, R. J. (2003). Secagem da madeira. Universidade Federal do Paraná.

Kollmann, F. F. P., & Côté, W. A. (1968). Principles of Wood Science and Technology. Springer-Verlag. https://doi.org/10.1007/978-3-642-87928-9

Kretschmann, D. E. (2010). Mechanical properties of wood. In Centennial (Ed.), Wood handbook: wood as an engineering material. Forest Products Laboratory, 5.1-5.46. https://www.fpl.fs.usda.gov/documnts/fplgtr/fplgtr190/chapter_05.pdf

Martins, M., Da Silva, J. R. M., Lima, J. T., Gonçalves, M. T. T., & Filipe, A. P. (2013). Simulação em uso dos pisos de madeira de Eucalyptus sp e Corymbia maculata. Cerne, 19(1), 151-156. https://doi.org/10.1590/S0104-77602013000100018

Ministerio del Ambiente. (2022). Bosque y pérdida de bosque. GeoBosques. https://geobosques.minam.Gob.pe/geobosque/view/perdida.php

Moreschi, J. C. (2014). Propriedades tecnológicas da madeira. Universidade Federal do Paraná.

Moya, R., & Muñoz, F. (2010). Physical and mechanical properties of eight fast-growing plantation species in Costa Rica. Journal of Tropical Forest Science, 22(3), 317-328. http://www.jstor.org/stable/23616661

Muñoz-Acosta, F., & Moreno, P. A. (2013). Contracciones y propiedades físicas de Acacia mangium Willd., Tectona grandis L. f. y Terminalia amazonia A. Chev, maderas de plantación en Costa Rica. Revista Chapingo Serie Ciencias Forestales y del Ambiente, 19(2), 287-303. https://doi.org/10.5154/r.rchscfa.2012.06.040

Panshin, A. J., & De Zeeuw, C. (1981). Textbook of wood technology. Structure, identification, uses, and properties of the commercial woods of the United States and Canada (vol. 1). Mc Graw Hill Book Co.

Pantigoso, J. A. (2009). Propiedades físicas y mecánicas de la capirona (Calycophyllum spruceanum (Benth.) hook ex Schumann) procedente de una plantación experimental en San Alejandro Ucayali – Perú [Undergaduate thesis, Universidad Nacional Agraria La Molina]. BAN. Biblioteca Agrícola Nacional. https://repositorio.lamolina.edu.pe/handle/20.500.12996/432

Porter, T. (2013). Wood identification & use. Servicio Nacional Forestal y de Fauna Silvestre. http://repositorio.serfor.gob.pe/handle/SERFOR/929

Servicio Nacional Forestal y de Fauna Silvestre. (2021). SERFOR fortalecerá la gestión de bosques y plantaciones forestales con fines comerciales en 9 regiones del país. Plataforma Digital Única del Estado Peruano. https://www.gob.pe/institucion/serfor/noticias/566180

Sibille, A. M. (2006). Guía de procesamiento industrial. Fabricación de muebles con maderas poco conocidas - LKS. WWF Perú. https://documentoskoha.s3.amazonaws.com/10727.pdf

Sotomayor-Castellanos, J. R., & Ramírez-Pérez, M. (2013). Densidad y características higroscópicas de maderas mexicanas. Base de datos y criterios de clasificación. Investigación e Ingeniería de la Madera, 9(3), 3-29.

Teixeira, D. E., Cunha, L. E., Wimmer, P., & De Andrade, A. (2019). Resistência à abrasão, dureza Janka e a correlação com outras propriedades em 14 espécies de madeiras tropicais brasileiras com potencial para utilização em pisos de madeira. Ciência da Madeira. Brazilian Journal of Wood Science, 10(2), 135-141. https://periodicos.ufpel.edu.br/index.php/cienciadamadeira/article/view/14156

Tuset, R., & Duran, F. (1979). Manual de Maderas Comerciales, Equipos y Procesos de Utilización. Hemisferio Sur.

Urban, R. (2011). Mecanismos de financiamiento para el sector forestal en el Perú. Diseño participativo de un mecanismo de financiamiento para el desarrollo del sector forestal en el Perú. FONDEBOSQUE; FAO Perú.

Ushiñahua, D. (2016). Comportamiento Fenológico Preliminar de Capirona en la Provincia de San Martín, Región San Martín. Instituto Nacional de Innovación Agraria. https://pgc-snia.inia.gob.pe:8443/jspui/handle/inia/213